PRESS FITTING FITTING/CONNECTOR SELECTION GUIDE

We are Béné Inox , your fluid processes partner, and we have been helping our customers to define their requirements and specifications for more than 50 years .

We have developed our press fitting fittings/connectors range to better meet our customers' requirements in this constantly evolving market.

Application environment :

Press fitting fittings/connectors allow you to create industrial piping networks completely safely, at a low cost!

They can be used to create networks for water treatment, drinking-water, air conditioning and heating or even for compressed air, inert gases or industrial vacuums etc.

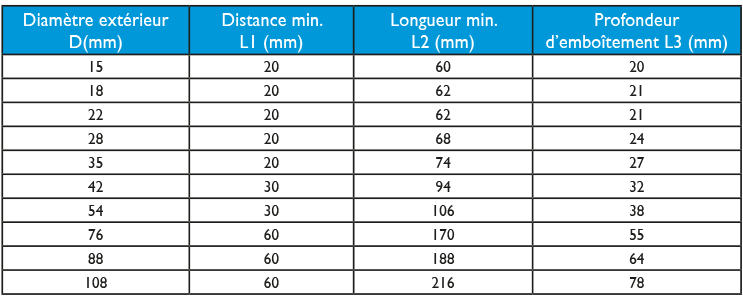

Range dimensions :

This range has specific dimensions.

Application conditions :

If you use the right press fitting tool, press fitting will only take you a few seconds. Our Béné Inox pressing collars are "M" type only .

Our products have diameters between 15 and 108. Their maximum operating pressure is 16 bars. It is best to check with a Béné Inox expert before you start product research for your installations .

When you use an EPDM gasket the maximum allowed vacuum is -0.95 bar for temperatures between -20°C and 120°C included.

This product's main certifications are from the CSTB (the French Scientific and Technical Centre for Building) for construction use and the ACS (French certification for drinking-water piping sanitary compliance) when you use these connectors with the EPDM gasket that they are assembled with in the standard model.

However, this range is not suitable for contact with food or beverage products.

Assembly :

Press fitting is a cold-working deformation process.

You should use a pressing collar with a suitable diameter and a press fitting tool which will allow you to apply a specific force that will spread out in an optimal way over the whole assembly during your press fitting assembly.

You will not be able to disassemble parts assembled by press fitting, it is this process that guarantees perfect connection sealing.

Equipment :

>> Please click here to find about more about our range of press fitting tools

- Press fitting tools : these are mains or battery powered electro hydraulic tools. A press fitting tool can apply a force of up to 32kN.

This is the force you need to deform a pipe and a connector enough to guarantee that this assembly will be completely sealed.

>> Please click here to find out more about our range of pressing collars and adaptors

- Pressing collars and adaptors : these are adaptation products which allow press fitting forces to be transmitted to your connector.

You should choose between the two types of pressing collars according to their diameter.

- Jaws : have diameters between 15 and 35mm, these crimp connectors.

- Circular pressing collars : have diameters between 42 and 108mm.

You need to position these around a connector and use an adaptor so that you can apply the required press fitting force to your assembly.

>> Please click here to find out more about our piping range

- Piping : press fitting pipes are rolled and welded according to the EN10312 standard, these pipes are available in 304L or 316L stainless steel.

>> Please click here to find out more about our range of connectors

- Connectors : our connectors are made from 316L stainless steel and are fitted with EPDM gaskets.

>> Please click here to access our tooling guide

- Accessories : we can help you choose from our Béné Inox press fitting tooling range :

pipe cutter for carbon steel (model 41177) | pipe cutter with quick telescopic extender (model 41181) and electric pipe cutter (model 41182),

deburrer (model 41178) and deburrer for electric pipe cutters (model 41180),

and depth indicator (model 41179).

Flow rate :

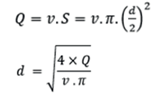

PYou will need to adapt the flow velocity of the fluids in your process to protect your installation, as well as to ensure acoustic comfort.

For example, it is generally recommended to use a flow velocity of 2-3m/s in a water network in order to avoid too turbulent flow.

Once you have defined the flow rate, you can establish the relationship between fluid velocity and cross-section, so that you can calculate the required piping diameter.

After you have done this please check our dimensioning table below (Range dimensions).

>> Please click here to find out more about our range of press fitting connectors

>> Please click here to find out more about our product selection and their special features

>> Please contact us to find out more on 0033 4 78 90 48 22 or by filling in our request for information form here�