SCREW SELECTION GUIDE

We are Béné Inox, a stainless steel products specialist with over 50 years of experience .

We help our customers to define their requirements and specifications for their fluid process projects.

All processes need to be fixed to existing infrastructure or be equipped with fixing elements.

This is why we propose a range of screws , bolts, nuts and fixations which contains over 13,000 part numbers .

This includes products made from a wide range of stainless steel grades; A1, A2 and other alloys which are highly resistant to corrosion .

These materials can be used in a number of very demanding sectors such as high pressure equipment, the petrochemical industry etc.

Our guide will give you tips for selecting the screws which are the most suitable for your process and installation safety requirements.

1. Application environment

You will need to use fasteners in many different sectors. We have designed products ranges that can be used in a number of different sectors such as :

- Construction (cladding, doors, windows etc.), Heating, Ventilation and Air Conditioning (heating or ventilation shafts etc.), various types of assemblies (e.g. household white goods) : please consult Range 10 - metal screws

- Roofing and terrace construction : Range 11 - wood screws

- Panelling and bodywork : Range 12 - sheet metal screws

2. Screw characteristics

We have many screw models that are specifically designed for certain usage requirements.

You need to take into account the following factors to choose the most suitable type of screw :

- the material that the screw will be fixed into

- the resistance, weight and thickness of its support

- screw material: you can use stainless steel screws in challenging and even aggressive environments

- the stresses and forces that will be applied to the assembled parts: the longer a screw, the higher its resistance will be.

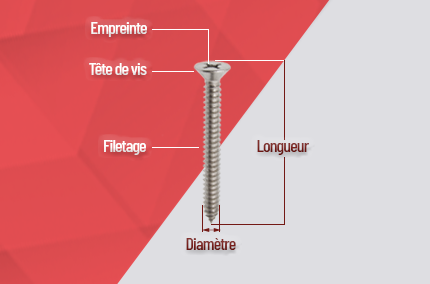

A screw is made up of :

- a head : we propose three different types of head: countersunk, round or flat

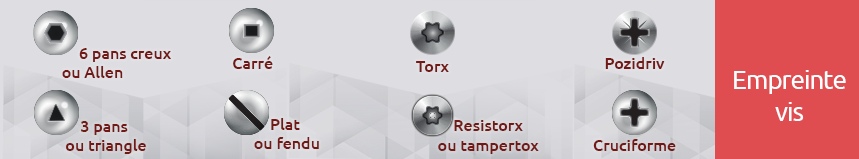

- a drive : this is the hollow space in the screw head that allows it to be screwed using, for example, a screw-driver.

- a body : this corresponds to the screw's diameter and length

- a tip : this is used as a guide during screwing

- a thread : this is the helical part which is present over either the whole length of the screw or just a part of it

3. Screw types

1. Metal screws - Range 10

This range of screw types covers our largest number of models according to their different lengths, diameters, head and thread types.

These screws need to be used with a nut or a female thread.

Certain screws are self-tapping, so you can pierce an element while you create a female thread and fix the screw into it.

2. Wood screws - Range 11

- Wood screws : these are threaded over around half of their length only and generally have small diameters and lengths.

- Wood Chipboard screws : these can be screwed without you needing to pierce a hole beforehand.

These screws will not split a wood surface when they are screwed into it.

The special feature of these screws is that they are very sharp, are threaded over their whole length and have a countersunk head.

3. Sheet metal screws - Range 12

These have a tip which is specifically adapted for use with sheet metal. However, to make screwing easier, you should make a hole in the sheet metal before you screw them into it.

These look like wood screws but they have a different type of thread.

Certain sheet metal screws are self-tapping, so you can pierce an element while you create a female thread and fix the screw into it.

4. Threaded shafts - Range 14

These are commonly used in construction work and mechanical assemblies. Threaded shafts have a thread over their whole length.

5. Tamper resistant screws - Range 22

These screws prevent the assemblies they are in from being disassembled, giving them an additional safety factor.

This screw range has several special features :

- Hexagon socket screws with centre pin, six-lobes with centre pin or "snake eyes" : you need a specific socket to screw in and unscrew these screws

- Tamper-proof hexagonal screws : once you have tightened these screws, their heads will break off making it impossible for them to be unscrewed

- One way screws : you will not be able to unscrew and remove these screws as their heads only allow them to be screwed in

4. Screw selection :

You need to carefully check what treatment has been applied to the material a screw is made from as during tightening screws can chip and this can favour the development of corrosion.

If a screw is not made out of stainless steel it is important that you check the quality of its alloy to make sure that it will not break when you are tightening it.

We recommend that you are very careful about the material you choose, as well as the type of screw head, according to the force you will need to apply.

If you want to find out more information or if you have any questions :

>> Please click here to find out more about our screw range

>> Please contact us to find out more (our sales team will get back to you as quickly as possible)�